AUTOMATION

and digitization

MAXIMUM FLEXIBLITY

DUE TO AUTOMATION

Automation means producing components efficiently, reliably and as far as possible without manual intervention. In this way, we increase machine running times and reduce unused resources, which in turn benefits our customers due to the increase in quality and greater flexibility.

Our high quality machines, extended by automated systems, can be used to automatically process the widest range of orders with the most diverse components/geometries.

Thanks to these automation solutions, we have optimised the production of parts even for very small batches, with maximum flexibility and a wide range of highly flexible handling options. This ensures fast, precise loading and unloading of our production machines and significantly reduces set-up times compared to conventional systems. Freely configurable workpiece storage (racks) enable optimum use of the resources available.

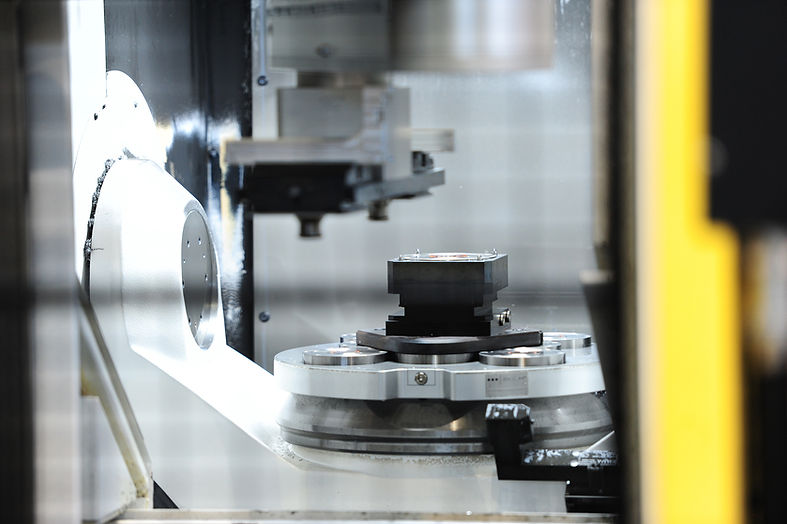

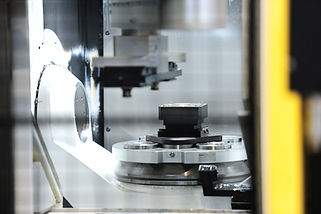

MODERN TECHNOLOGIES

The zero-point clamping system we use is the modern alternative to the conventional T-slot table: set-up times are reduced and the machine capacity is increased. Maximum flexibility and process reliability are guaranteed throughout the entire production process. High clamping force with the highest accuracy.